4.6.2 Operator Level 2 Parameters

1. Press  to scroll through a list of parameters. (Press

to scroll through a list of parameters. (Press  to scroll back).

to scroll back).

2. Press  or

or  to adjust the value of a selected parameter.

to adjust the value of a selected parameter.

3. Press  to accept the value

to accept the value

The table below shows all parameters that are available depending on features configured. For factory default settings see Appendix A.

| Parameter Mnemonic | Parameter Description | Further Information | ||||||||||||||||||||||||||||||||||||||||||||||

| SP | Current setpoint | This shows the current (working) setpoint which is read only when the controller is in ‘Manual’ or ‘OFF’ mode. It is not shown here when the controller is in Auto mode. | See also section 4.9 ‘Auto, Manual, Off Mode’ | |||||||||||||||||||||||||||||||||||||||||||||

| oP | Output power |

This shows the working output demand which is read only when the controller is in ‘Auto’ or ‘OFF’ mode. In a heat/cool temperature control application, 100.0% = full heating, -100.0% = full cooling For heat only 100.0 – full heating; 0.0 = no heating. For cool only 100.0 = full cooling; 0.0 = no cooling. (All limited by op.Hi and op.Lo). When the controller is in Manual mode the output power demand can be adjusted using |

||||||||||||||||||||||||||||||||||||||||||||||

| Ac.AL | Alarm Acknowledge |

An alarm can be acknowledged by selecting YES. By default the |

See also section 4.3.4 ‘To Acknowledge an Alarm’ | |||||||||||||||||||||||||||||||||||||||||||||

| A-N | Loop Mode | Select this for Auto, Nan, OFF operation (Off = control outputs inhibited). | See also section 4.9 ‘Auto, Manual, Off Mode’ | |||||||||||||||||||||||||||||||||||||||||||||

| t.St | Timer Status |

This displays the current status of the timer. res = reset, rUn =counting, HoLd = hold, End = timed out. |

See also section 4.11. ‘Timer operation’ | |||||||||||||||||||||||||||||||||||||||||||||

| E.rst | Energy Counter Reset | nonE | No action | See also section 4.10 | ||||||||||||||||||||||||||||||||||||||||||||

| E.PAr | To reset the partial value | |||||||||||||||||||||||||||||||||||||||||||||||

| E.tot |

To reset the total value. Available only if the partial value, E.Par, has been previously reset and its content is equal to zero. |

|||||||||||||||||||||||||||||||||||||||||||||||

| Unit | Display Units |

Choose from none, OC, OF. If OC or OF are selected then the units appear momentarily in the display when the setpoint is changed. If ‘none’ is selected then no units are displayed when the setpoint is changed. |

||||||||||||||||||||||||||||||||||||||||||||||

| SP.Lo | Setpoint Low Limit. | The setpoint low limit is automatically set depending on the ‘Input Type’ selected using the ‘P’ code P1. It can be further limited between the Setpoint High Limit value and the Low Range Limit value using  or or  . . |

||||||||||||||||||||||||||||||||||||||||||||||

| SP.Hi | Setpoint High Limit. | The setpoint high limit is automatically set depending on the ‘Input Type’ selected using the ‘P’ code P1. It can be further limited between the Setpoint Low Limit value and the High Range Limit value using  or or  . . |

||||||||||||||||||||||||||||||||||||||||||||||

| SP1 | Setpoint 1 | Two setpoints are available. These can be pre-set ready to be selected by the Setpoint Select parameter below, or via a digital input if configured. | ||||||||||||||||||||||||||||||||||||||||||||||

| SP2 | Setpoint 2 | |||||||||||||||||||||||||||||||||||||||||||||||

| SP.SL | Setpoint Select | To select between SP1 and SP2. Read only when SP selection is configured by a digital input. | See also ‘P’ code P51 and P52 section 5.2.16 | |||||||||||||||||||||||||||||||||||||||||||||

| SP.rr | Setpoint Rate Limit |

This applies a limit to the rate at which either SP1 or SP2 changes. When turned OFF no limit is applied to the rate of change of setpoint. Select a value between 0.1 to 3000 units per minute to ramp to a new setpoint. Whenever the selected setpoint is changed, the controller will servo to the current PV then ramp at the rate selected in SP.rr to the new value. If switching between setpoints 1 and 2 the controller will servo to the current PV then ramp to the new setpoint value. If the power to the controller should fail during a ramp then the controller setpoint will servo to the current PV when the power is restored and then ramp to the selected setpoint value. |

||||||||||||||||||||||||||||||||||||||||||||||

| AL1 | Alarm 1 Setpoint | Sets the level at which alarm 1 operates | See also section 4.3, ‘ Alarms’ | |||||||||||||||||||||||||||||||||||||||||||||

| AL1.H | Alarm 1 Hysteresis | Hysteresis sets the difference between alarm 1 switching on and switching off. It is designed to prevent random switching if the PV is noisy or changing significantly. | ||||||||||||||||||||||||||||||||||||||||||||||

| AL2 | Alarm 2 Setpoint | Sets the level at which alarm 2 operates | ||||||||||||||||||||||||||||||||||||||||||||||

| AL2.H | Alarm 2 Hysteresis | Hysteresis sets the difference between alarm 2 switching on and switching off. It is designed to prevent random switching if the PV is noisy or changing significantly. | ||||||||||||||||||||||||||||||||||||||||||||||

| AL3 | Alarm 3 Setpoint | Sets the level at which alarm 3 operates | ||||||||||||||||||||||||||||||||||||||||||||||

| AL3.H | Alarm 3 Hysteresis | Hysteresis sets the difference between alarm 3 switching on and switching off. It is designed to prevent random switching if the PV is varying significantly. | ||||||||||||||||||||||||||||||||||||||||||||||

| A.tUn | Auto-Tune Enable. | OFF (disable), On (enable), FAIL (Auto-tune has been unsuccessful). This may be due to an open loop condition. | See also section 7.2, ‘Tuning’ | |||||||||||||||||||||||||||||||||||||||||||||

| Pb | Proportional Band | Range 1 to 9999 engineering units (e.g OC). Default 20. | See also section 7 ‘Control’ | |||||||||||||||||||||||||||||||||||||||||||||

| Ti | Integral Time | Range OFF, 1 to 9999 seconds (default 360). | ||||||||||||||||||||||||||||||||||||||||||||||

| Td | Derivative Time | Range OFF, 1 to 9999 seconds (default 60) | ||||||||||||||||||||||||||||||||||||||||||||||

| cb.Hi | Cutback High | Range Auto, 1 to 9999 display units (default Auto = 3*Pb) | ||||||||||||||||||||||||||||||||||||||||||||||

| cb.Lo | Cutback Low | Range Auto, 1 to 9999 display units (default Auto = 3*Pb) | ||||||||||||||||||||||||||||||||||||||||||||||

| Nr | Manual Reset | Range -100 to 100 (default 0.0) | ||||||||||||||||||||||||||||||||||||||||||||||

| r2G | Relative Secondary (Cool) Gain | Range 0.1 to 10.0 (default 1.0) | ||||||||||||||||||||||||||||||||||||||||||||||

| HyS | Primary Output Hysteresis | Sets hysteresis for all outputs configured for ON/OFF Heating. It is available for a single action ON/OFF controller. Range 1 to 3000 display units (0.1 to 3000 or 0.01 to 300.0 depending on the number of decimal places configured). | See also section 7.2.11. | |||||||||||||||||||||||||||||||||||||||||||||

| HyS.C | Secondary Output Hysteresis | Sets hysteresis for all outputs configured for ON/OFF Cooling in a double action controller. Range 1 to 3000 display units (0.1 to 3000 or 0.01 to 300.0 depending on the number of decimal places configured). | ||||||||||||||||||||||||||||||||||||||||||||||

| d.bnd | Dead Band | Dead Band Between Heating And Cooling; Range OFF, 0.1 to 100% of cooling Pb. (Off = no deadband) | ||||||||||||||||||||||||||||||||||||||||||||||

| 1.PLS | Output 1 Minimum Pulse Time |

Time proportioning is a method of delivering power to the load by switching the output on and off for accurately measured time intervals. To deliver 50% power the output on period will be the same as the off period. When set to Auto, the minimum pulse time that can be set is 100ms. A very low power demand is represented by a short on pulse of 100ms duration followed by a correspondingly long off time. As the power demand increases the on pulse becomes longer and the off pulse becomes correspondingly shorter. For a 50% power demand the on and off pulse lengths are the same (at 200ms on and 200ms off). The choice of minimum pulse time is determined by two factors:

1. The stability of the control. If the minimum pulse time is set too long then the process variable will appear to dip during the off times. This may cause apparent control instability. 2. The life of the control actuator. Relay outputs or mechanical contactors may wear out prematurely if the minimum pulse time is set too short.

Setting to Auto is suitable for logic outputs, not driving a mechanical device. If the control device is a relay or contactor the minimum on time should be set greater than 5 seconds (for example) to prolong relay life.

By way of illustration, the ON/OFF times are shown in the table for a typical relay setting of 5 seconds and a typical logic setting of 0.1s:-

For relay outputs the range is Auto or 0.1 to 150.0 seconds (default 5.0). For logic outputs the range is Auto or 0.1 to 150.0 (default Auto = 100ms)

|

||||||||||||||||||||||||||||||||||||||||||||||

| 2.PLS | Output 2 Minimum Pulse Time | |||||||||||||||||||||||||||||||||||||||||||||||

| 3.PLS | Output 3 Minimum Pulse Time | |||||||||||||||||||||||||||||||||||||||||||||||

| 4.PLS | Output 4 Minimum Pulse Time | |||||||||||||||||||||||||||||||||||||||||||||||

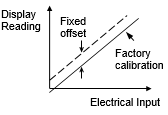

| ofs | PV Offset | PV Offset applies a single offset to the temperature or process value over the full display range of the controller. It has the effect of moving the curve up a down about a central point as shown. |

|

|||||||||||||||||||||||||||||||||||||||||||||

| FiLt | PV Input Filter Time | A first order filter provides damping of the input signal. This may be necessary to prevent the effects of excessive process noise on the PV input from causing poor control and indication. More typically used with process inputs. Settable range oFF 0.1 to 100.0 seconds. Default value 1.6 seconds. | ||||||||||||||||||||||||||||||||||||||||||||||

| oP.Lo | Output Low Limit | Range -100.0% to P36 for a Heat/Cool controller; 0.0% to P36 for a heat only controller. The upper range is limited to the value set by op.Hi. |

Op.Lo and oP.Hi are also limited by the value of the Safe Output Power Limit set in configuration level by P36. This is to ensure that the Safe Output Power cannot be overridden by the Output High and Low Limits.

For example, if the Safe Output Power Limit is set to +10.0, oP.Lo can be set between -100.0 and +10.0 (0.0 and +10.0 for heat only or cool only) and oP.Hi can be set between +10.0 and +100.0.

Note: by default P36 is set 0.0 which means that for a heat only (or cool only) controller oP.Lo is fixed at 0.0. |

|||||||||||||||||||||||||||||||||||||||||||||

| oP.Hi | Output High Limit |

Range P36 to +100.0% .

Note: For a cool only controller oP.Hi represents the maximum cooling power limit. |

||||||||||||||||||||||||||||||||||||||||||||||

| Ld.A | Load Current | Reads the current applied to the load (elements). Read only. |

Only shown if the CT function is configured.

See also section 5.2.12, ‘Current Transformer’. |

|||||||||||||||||||||||||||||||||||||||||||||

| LE.A | Leak Current | Reads the leakage current in a load. Read only | ||||||||||||||||||||||||||||||||||||||||||||||

| Ld.AL | Load Current Alarm Threshold | To set an alarm if the load current is exceeded. | ||||||||||||||||||||||||||||||||||||||||||||||

| LE.AL | Leakage Current Alarm Threshold | To set an alarm if the leakage current is exceeded. | ||||||||||||||||||||||||||||||||||||||||||||||

| Hc.AL | Overcurrent Alarm Threshold | To set an alarm if the load current is exceeded beyond a ‘safe’ limit. | ||||||||||||||||||||||||||||||||||||||||||||||

| t.dUr | Set Timer Duration | Only shown if the timer function is configured | Section 4.11, ‘Timer Operation’ | |||||||||||||||||||||||||||||||||||||||||||||

| t.tHr | Timer Start Threshold | Only shown if timer type = Dwell | ||||||||||||||||||||||||||||||||||||||||||||||

| SS.SP | Soft Start Setpoint | Only shown if timer type = soft start | ||||||||||||||||||||||||||||||||||||||||||||||

| SS.oP | Soft Start Output Power Limit | Only shown if timer type = soft start | ||||||||||||||||||||||||||||||||||||||||||||||

| t.EL | Time Elapsed | Read only indication of the time elapsed | ||||||||||||||||||||||||||||||||||||||||||||||

| t.rE | Time Remaining | Time remaining before the timer times out. This value can be extended while the timer is running or after it has timed out. | ||||||||||||||||||||||||||||||||||||||||||||||

| E.PAr | Energy Counter Partial Value | This parameter is read only and is intended to measure energy usage for specific batches. | Section 4.10 ‘Energy Usage’. It is also possible to configure the second/third line of the display to read this value – section 5.2.19, ‘P’ Codes P74 and P75 | |||||||||||||||||||||||||||||||||||||||||||||

| E.tot | Energy Counter Total Value | This parameter is read only and is intended to measure energy usage for a total process which may consist of a number of batches. | ||||||||||||||||||||||||||||||||||||||||||||||

| UcAL | User Calibration | Select the point for two point offset. idLe (not calibrating), Lo (low point cal), Hi (high point cal), rESt (remove user cal) | Section 4.7 | |||||||||||||||||||||||||||||||||||||||||||||

| c.Adj | Calibration Adjust | Adjust for two point offset If uCAL= Lo or Hi | ||||||||||||||||||||||||||||||||||||||||||||||